compression test cranking speed|engine compression test chart : fabrication Running compression at idle should be 50-75 PSI (about half cranking compression). Snap throttle compression should be about 80% of cranking compression. Let’s analyze the results . web27 de mai. de 2014 · 回答 1 查看 285 关注 0 票数 1. 我正在尝试在Windows7 (64位)计算机上安装一个传统的VB6客户端,它可以与用Visual C++编写的DCOM 服务器 通信。. 我知道我需要运行 CLIREG32 并将 .VBR 文件作为参数传递给它。. 我试着这样做:. clireg32 myvbrfilehere.vbr -s -d -l .

{plog:ftitle_list}

WEB16 de jan. de 2024 · Pocket Games Soft 游戏介绍. Pocket Games Soft 是世界一流的手机游戏开发商。 致力于在iOS,Android和HTML5平台上提供前所未有,身临其境的移动游戏解决方案。 麻将胡了. 麻将三缺一,等您来开杠! 麻将胡了2. 人气游戏《麻将胡了2》火热来袭! 摇钱树. 摇一摇手游新体验,拜一拜财源滚滚来! 发财鱼虾蟹. 鱼虾蟹经典再现,连赢连 .

You will hear the cranking speed slow, as the tested cylinder, comes up on it’s compression stroke. Note how fast the compression increases and write down the highest reading. Test all cylinders the same way, with the same number, of compression strokes. . I've read a number of different recommendations on how many times to cranks the engine during a compression test. I've read those that say to crank until you reach a stable .Running compression at idle should be 50-75 PSI (about half cranking compression). Snap throttle compression should be about 80% of cranking compression. Let’s analyze the results . You will be able to hear the cranking speed slow as the tested cylinder comes up on its compression stroke. Note how fast the compression increases and record the highest reading. Test all cylinders the same way with .

An engine compression test measures the pressure within the engine cylinders during the compression stroke. This pressure indicates how effectively the engine compresses the air-fuel mixture, which is essential for .

Idle speed is usually 5-10 times faster than cranking speed, so the passage or valve usually allows enough airflow to get a compression reading within a few percent of the wide-open-throttle (WOT) value.Jul 19, 2016 A compression test is performed by then cranking the engine. This will then allow the gauge to read multiple compression strokes from that cylinder. Allow the engine to spin until the gauge has received at least six “puffs”, then release . Cranking speed can affect the compression readings during a compression test. Faster cranking speed may result in higher compression pressure readings. Can you hand crank a compression test? Hand-cranking an engine for a compression test is possible for some small engines, but it's generally more accurate and convenient to use a starter motor .

Keystone piston rings are designed to expand during the compression stroke of the engine. At engine cranking speed, the Keystone piston rings do not fully expand. This results in unstable readings for cylinder compression. As a result Caterpillar does not recommend performing compression tests on engines that use Keystone piston rings.

running compression vs cranking

Note: The engine cranking time for the compression test should be less then 10 seconds and at 30 second intervals. 5. Crank the engine with the starter motor for 5 seconds to remove any foreign substances from the cylinders. . Prior to taking a compression reading, verify the cranking speed is greater than 300 RPM. If the cranking speed is . Crank the Engine: Have an assistant crank the engine by turning the key in the ignition while you observe the gauge.Allow the engine to crank for about 5-10 seconds or until the gauge needle stabilizes at its highest reading. Record the Reading: Note the peak pressure reading on the gauge and record it on paper.; Repeat for All Cylinders: Repeat the process for .The purpose of this test is to evaluate the in-cylinder pressures of a gasoline engine during cranking using the WPS500X pressure transducer. . as the piston cycles through its compression stroke (540° to 720° after TDC), indicating intake valve closure. . the RPM value indicates the engine’s cranking speed. Note. Actual pressures vary . I've seen many times a compression test done at idle and the results come out half or much less than a proper test. Top. rp930 Pro Posts: 231 Joined: Wed Dec 11, 2013 4:47 am . ya cranking speed is normal, ( healthy battery in both cars) Ill try another tester, and at WOT. both engines run good. Lots of oil pressure. Top. swatson454 Guru

Any rate, I did this test on my truck, and the crank is nowhere near as consistent as in Ron's video. I can't post links yet, since my account doesn't have enough posts, but if you go to youtube and search "6.0 crank speed compression test", my video should be the first to pop up. Max Sauer is my channel on youtube. What are your thoughts?

The compression test is a procedure that measures the ability of a cylinder to contain the pressure produced while the piston is traveling upward with both valves closed. . Spin the engine over and listen to see if you can detect any cylinders that pick up speed rather than squeezing air. . Briefly crank the engine to test each cylinder.

Compression testing guides tell you to hold the engine’s throttle wide open during a compression test; this post tells you why it may or may not matter. Skip to content. 1-800-440-5582. . (with no load). Idle speed is usually 5-10 times faster than cranking speed, so the passage or valve usually allows enough airflow to get a compression .

how to use compression tester

how to check cylinder compression

good compression test numbers

Crank the engine at least 4 times to complete the test. Turn the key as far as it will go in the ignition, then release it. Do this about 4 or 5 times without shutting off the vehicle at all. The engine will be running throughout the entire process. When you’re done, check the compression gauge to get the test result. This could be, for example, a low cylinder compression which is another source of trouble for the DMF’s longevity as the constantly changing cranking speed, where say three cylinders have good compression and one has poor compression so is easier to turn, added to doubtlessly erratic or less-smooth engine idle, provides additional stresses .

There are some variables that affect the readings obtained from compression testing, including: cranking speed, altitude, temperature, worn camshaft lobes, and; high-performance long-duration profile camshafts. The cranking speed needs to be maintained the same for each cylinder. This may mean jumping your battery to maintain the speed.

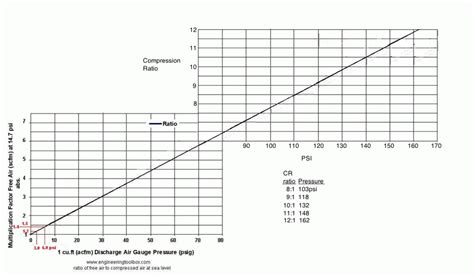

I did a compression test on my little SBC 292 at cranking speed, with out spark plugs and carb at full throtle, engine warmed a little. It have 10:1 CR, and a XE274H cam. The heads are full ported 896s and I equalize the chambers volume myself . The lowest readings are 165 psi and 170 psi is the highest .

THE COMPRESSION GAUGE. This gauge is designed to indicate the individual pumping ability of each cylinder of an engine at cranking speed. Consequently, to get a meaningful reading, intake flow . This fast cranking speed is very noticeable. The ignition system is creating and delivering spark to all 4 cylinders. . The next step is to do a 'wet' compression test and find out if the problem is due to bad piston rings or bad . 100 psi is minimum could be due to low comp motor or due to hot perf cam with a lot of duration/overlap effectively reducing cyl pressure when cranking motor over at slow speed for comp test. When my 396/325 was bone stock with whimpy stock gm cam & stock 10.25.1 compression it had cranking comp of 180-185psi on all 8 cyls.

Speed-Talk.com. Board index. Technical. Engine Tech. Speed-Talk Google Search . 2007 8:07 pm Location: cranking compression test. Post by chevy155 » Mon Jan 19, 2009 11:35 pm. Hi everyone, have just done a compression test on my 13.1, 434sbc. Engine to operating temp, open throttle blades, plugs out crank 10 revs. . 108 lobe sep angle .It is important to remember to prepare the vehicle for testing so that the engine will not start during cranking. In the relative compression test in PicoDiagnostics, the result is scaled to show the highest cylinder as 100%. . Sufficient cranking speed; Adequate intake and exhaust flow to achieve the correct peak pressure (no restrictions). Don't know cranking speed of the 230 but I have a Vapor on my CRF250X and cranking speed is up around 400+ if the motor doesn't start. Normally I can't accurately tell cranking speeds because of the tachometer sampling rate and the engine's short start cycle. I usually see a reading about 350rpm, then a 700ish, and then the engine is running.

The battery is rated for 925. I'm going to install a known good battery with 960 CCA's (verified) to see if it improves crank speed while cold.I haven't gotten into the compression on the machine I'm working on primarily because the two machines run identically once they fire and neither shows any sign of low compression.

So I then checked the cranking compression pressures. Here's what I came up with. 1)225 2)230 3)225 4)205 5)205 6)0 7)205 8)215 Tried checking #6 twice, couldn't get any reading at all. ??? Does this compression test tell me anything and can it help me? Anyone have any thoughts? Here's the engine specs: 383 SBC-----KB 10.7:1 Flat-Top Hypers GM .This test also called labral crank test or compression rotation test is used to identify glenoid labral tears and assess an unstable superior labral anterior posterior (SLAP) lesions. [1] Technique [ edit | edit source ]

Single Yarn Strength Tester store

Since you'll never even reach idle speed while cranking an engine, the governor holds the throttle full open for you. You can't do a test at anything except WOT on on an engine with a governor. . Throttle position for a compression test on our tractors is irrelevant, but on other engines, means a whole lot. Hope this helps clear a few things .

This is a low cranking compression, especially when you compare it to engines like the ZZ4 350ci/345hp crate engine that makes around 190 psi or the current HT 383 with 9.1:1 compression and a big . Our class was introduced with a compression ratio rule. I quickly discovered by luck (low battery) that cranking speed , when slowed down, compression test would read lower. Worked great until others discovered same thing. . You can have 30 to 40 degrees total overlap wipes out that much crank speed compression. Reply 08-08-2017, 09:20 PM #6 . Crank the engine over using the starter motor five compression strokes. Record the compression reading on the gauge. Note: Verify that the batteries voltage does not go low enough to affect engine cranking speed. If the cranking speed is affected then the results will be inaccurate. If needed connect a battery charge to maintain battery voltage. After you have removed all the spark plugs, thread the appropriate compression test hose into the No. 1 spark plug hole and connect the hose to the compression gauge. Now you’re ready to perform the test on cylinder No. 1. As you are cranking the engine over, you must have the throttle at wide open before you engage the starter.

Yarn Strength Tester store

WEBThe Death Row Chronicles. Available on BET. This docuseries features interviews with Death Row Records insiders (including co-founder Suge Knight), archival footage and previously undisclosed details about Tupac .

compression test cranking speed|engine compression test chart